현대제철 통합보고서

현대제철 통합보고서

Environment

Environmental Management3.2.1

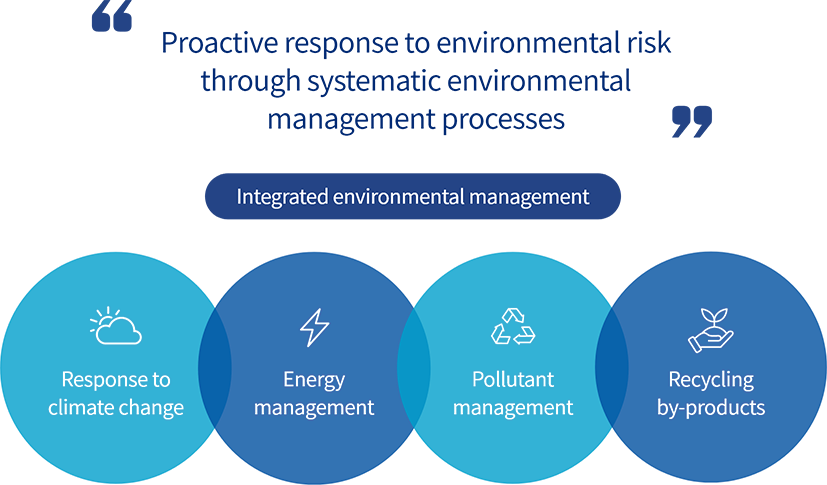

Through compliance with environmental regulations and environmental management, Hyundai Steel strives to realize an economy that deals with steel, an environmentally-friendly resource, in the most eco-friendly possible. To minimize environmental risks, all of our business sites have dedicated environmental groups for each sector, which conduct environmental impacts that could arise in the course of business activities. In addition, we operate an environmental management system to actively respond to environmental regulations, develop eco-friendly products and services, and conduct CSR activities for environmental protection, thus fulfilling our corporate social responsibilities.

Environment and Energy Policy

Analyze management activity risks

- Proactive response to government policies and regulations

- Gather information on environmental and energy issues

- Predict, evaluate and implement response strategies for influential factors

Invest efficiently energy and resources

- Procurement: green procurement of fuel, raw materials, equipment and energy

- Production: optimize process utility input and reduce GHG emissions

- Conserve water resources and manage risk

Minimize emissions and pollution

- Optimally operate and monitor pollutant measurement/prevention facilities

- Prevent emission of pollutants

- Recycle and add value to by-products/waste

Fulfill corporate ethical and social responsibilities

- Raise brand value through campaigns, win-win growth with communities and CSR activities

- Develop projects for alternative resources/energy and offsetting

Regular Internal Environmental Inspections

Hyundai Steel conducts internal inspections on a regular basis as a preemptive response to external inspections in order to reduce the unseen potential for violations of environmental regulations. An inspection team comprising persons in charge from each sector conducts weekly on-site inspections of each area. If a potential violation of environmental regulations is spotted, relevant training for environmental management is implemented, and risk awareness training and improvement plans are put in place. In 2020, our internal inspections yielded 415 improvements to potential risks.

| Laws | Contents | Our Response |

|---|---|---|

| Act on the Integrated Control of Pollutant-Discharging Facilities | Effective in 2017, the Act establishes permitted standards for each type of worksite, integrating 10 permit standards previously used for different aspects of the environment, such as air, water quality, etc. | Hyundai Steel is applying the best available methods at facilities that discharge pollutants by improving management processes, analyzing emission impacts across all worksites, and preemptively studying the permitted emissions levels for each worksite to effectively reduce pollutant discharge, and we have prepared measures to make practical improvements to the environment. |

| Framework Act on Resource Circulation | Implemented in 2018, the Act outlines a new system to reduce waste and encourage recycling in all stages from production to distribution, consumption and disposal, thereby protecting the environment and establishing the foundation for a circular economy. | Hyundai Steel seeks to ensure by-products should be perceived as resources that can be recycled, rather than waste to be disposed of, and accordingly take preemptive actions to promote resources circulation through per-unit management of by-product output, new technology research, increased by-products input to processes, and collaboration with other companies on recycling. |

| Act on Liability for Environmental Damage and Relief Thereof | Effective from 2016, the Act establishes a system for effective damage relief with clear standards for compensation and eases the burden of proof on the injured party, providing a means of fair and speedy relief in cases of damage from environmental pollution. | Hyundai Steel maintains environmental liability insurance to facilitate swift compensation for the injured party in case of environmental pollution incidents, and we have strengthened environmental supervision at our worksites to prevent environment-related incidents. |

| Special Act on the Improvement of Air Environment in Air Quality Management Areas | Enacted in April 2020, the Act seeks to improve air quality by controlling air pollutants broadly and systematically according to regional characteristics. | Hyundai Steel is subject to the emission cap regulation and hence we comply with the mandatory installation of telemonitoring systems (TMS) on smokestacks and work to ensure that all of our business sites can comply with the smokestack emissions cap regulations. |

Reduction of Raw and Subsidiary Materials Consumption

Despite the domestic and international economic slowdown caused by the Covid-19 pandemic, Hyundai Steel continues to hold monthly meetings attended by key senior managers, reviewing efforts to reduce costs and proactively addressing environmental risks. Furthermore, these meetings, which previously focused on monthly production performance, now extend to production techniques, energy and logistics. They include a preliminary review of expected performance in the current month, and preemptive action to reduce costs. Hyundai Steel will continue working to reduce its raw and subsidiary material consumption and to lower not only its production costs but its emissions of greenhouse gases and other air pollutants.

Operation of the Hyundai Steel Environmental Improvement Council

Since 2019, Hyundai Steel has operated the Environmental Improvement Council in order to transparently share and exchange information with local communities. Bringing together a total of 17 representatives of Hyundai Steel and relevant institutions, the Council discusses matters including the status of environmental management at steelworks, such as TMS, pollutants concentration levels and air pollutant emissions, as well as issues related to the steelworks and local environment, including air pollutants reduction and the installation of blast furnace bleeders. Since February 2020, we have deployed cleaning trucks (one sprinkler truck, one sweeper truck) to reduce fine dust on roads near our steelworks. The Council discloses environmental information relating to our steelworks through Danjin municipality's homepage and, starting March 2021, began using an automatic odor measurement network installed at three locations near the southern end of the Danjin Steelworks last year and disclosing the measured data on our website. The Hyundai Steel Environmental Improvement Meetings will continue exploring concrete measures to improve the environment at our steelworks and address pending issues for the development of local communities.

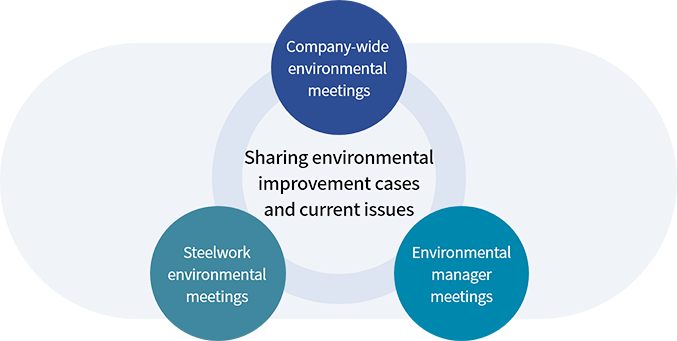

Systematized Environmental Meetings

Hyundai Steel systematically organizes environmental meetings to raise awareness of the importance of environmental management to the company's leadership and to build a consensus across the company. Company-wide meetings are organized every quarter, while monthly sessions are convened at steelworks and among environmental managers. Attendees share environmental improvement cases and issues at each worksite and collectively formulate solutions. In addition, we maintain an effective communication system with executive management through regular, company-wide environmental meetings.

Diagram of the environmental meetings system

ESG Bond Issuance

As part of eco-friendly management, Hyundai Steel is considering expanding the issuance of the green bonds1) we issue under our ESG bond2) program. This is due to overwhelming demand among institutional investors for our green bond issue in January 2021, when demand was forecast at KRW 250 billion, but actual

demand was KRW 2.07 trillion, exceeding the forecast by eight fold. ESG certification for this

bond issuance was conducted by a credit rating agency, and Hyundai Steel received the highest rating of GB13)(E1/M1). When a company undergoes the certification by a strict ratings agency, and its rating is managed on a regular basis through follow-up evaluations, it gains greater confidence among investors.

The funds raised from these green bonds, which reflect Hyundai Steel's active commitment to environmental investment, will be invested entirely in green projects until maturity.

The funds raised from these green bonds, which reflect Hyundai Steel's active commitment to environmental investment, will be invested entirely in green projects until maturity.

- 1) ESG Bonds: Bonds issued to fund social responsibility investments such as environmental, social and governance improvements, broadly categorized into three types: green bonds, social bonds and sustainability bonds.

- 2) Bonds whose use is limited to eco-friendly activities and green projects such as carbon reduction, new and renewable energy and electric vehicles.

- 3) The highest rating(E1/M1)given in the Part 2 evaluation dealing with fund management, operation systems and transparency in evaluations for green bond rating(GB1~GB5)and ESG bonds.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.