Environmental Management

Hyundai Steel strives to realize a circular economy by dealing with steel, an environmentally-friendly resource, in the most eco-friendly way possible through compliance with environmental regulations and environmental management. Above all, we have dedicated environmental groups by sector across all business sites, which monitor environmental impacts that may arise in the course of our business operations. In addition, we operate an environmental management system to actively respond to environmental regulations, develop eco-friendly products and services, and conduct CSR activities for environmental protection, thus fulfilling our corporate social responsibilities.

Environmental Management Process

Response to climate change

Pollutants management

Recycling by-products

Energy management

Environment and Energy Management Policy

- Risk analysis of management activities

- · Proactive response to government policies and regulations

- · Information gathering on environment and energy issues

- · Prediction, evaluation and actions on environmental impacts

- Efficient use of energy and resources

- · Green purchases of fuel, raw materials, equipment, and energy

- · Optimization of process inputs and GHG reduction

- · Reduction of water pollution and risk management

- Minimization of emissions and pollution

- · Measuring and containment of pollutants

- · Optimized operation and monitoring of pollution prevention facilities

- · Recycling by-products and added-value creation

- Fulfilling corporate ethical and social responsibilities

- · Enhancing brand value through win-win growth with communities and CSR activities

- · Use of alternative resources and energy

Environmental Management System

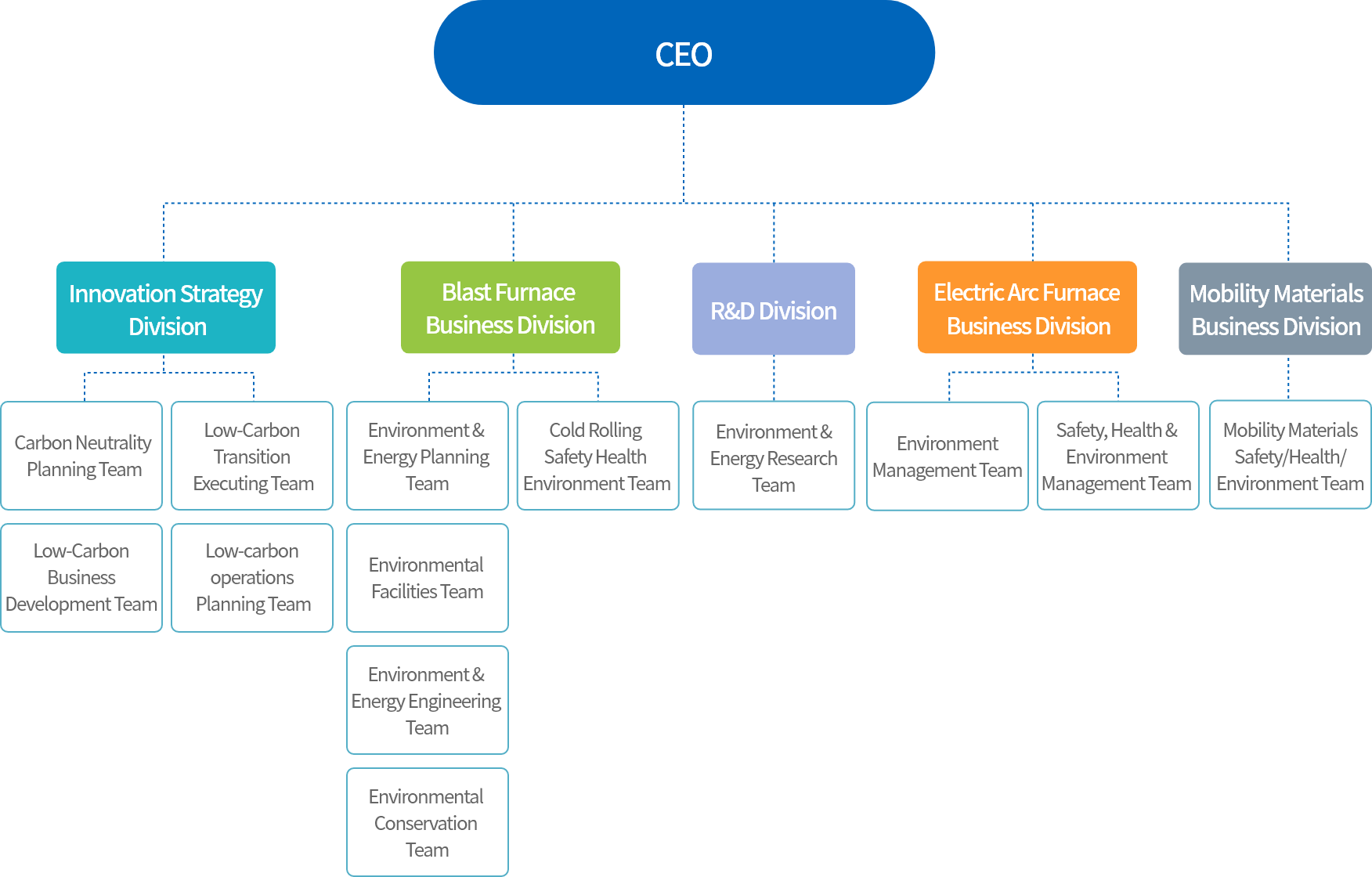

In April 2021, Hyundai Steel converted its organization into a business division system to strengthen responsible management and reorganized its environmental organization to actively implement environmental management in the field. In February 2021, the Low Carbon Process Research Group that specializes in carbon-neutral technology development was established in the R&D Division. Additionally, at the beginning of this year, the 'Carbon Neutrality Execution Division' was launched to serve as a control tower of carbon neutral strategies, and mid-to long-term transition of relevant systems. With such alterations, Hyundai steel reinforced the structure to take a leap forward as an eco-friendly steel maker.

Transition to the Integrated Environmental Management System

The Ministry of Environment proclaimed 'The Act on the Integrated Control of Pollutant Discharging Facilities' in 2015 and has adopted an integrated environmental management system in phases since 2017. The new system integrates seven laws and 10 permits and reports which were previously separated by environmental sector (air, water, waste, etc.), whereby the Ministry of Environment holds the sole authority to grant approvals. The purpose of this integration scheme is to better reflect the distinctiveness of respective companies, industries, environmental impact and to adopt the most optimized methodologies available (technically or economically feasible means) to minimize environmental impact. All business sites of Hyundai Steel, including the Incheon Works and the Dangjin Integrated Steelworks, already acquired an integrated environmental permit in 2021. We will continue our efforts to mitigate the environmental impact of pollutants by promoting timely implementation of requirements such as permitted emission standards.

Major Environmental Laws and Our Responses

| Laws | Contents | Our Response |

|---|---|---|

| Act on the Integrated Control of Pollutant-Discharging Facilities | Taking effect from 2017, the Act integrated 7 legislations and 10 declarations of permissions to simplify procedures, and set up customized criteria for each company. | Hyundai Steel takes measures to effectively reduce pollutant discharge and make practical improvements for the environment by applying the best available methods to pollutant-discharging facilities, improving management processes, analyzing impacts of pollutant discharge across all business sites, and pre-examining discharging criteria. |

| Framework Act on Resources Circulation | Taking effect from 2018, the Act introduced new systems to reduce waste and encourage recycling in all steps from production, distribution, consumption and disposal as a purpose to protect the environment as well as establish a basis for a circular economy. | Hyundai Steel seeks to ensure by-products are perceived as resources that could be recycled, not as disposal waste. To take pre-emptive action, Hyundai Steel manages by-products per unit, invest in new technological developments, expand applying in processes, and collaborate with other industries |

| Act on Liability for Environmental Damage and Relief Thereof | Effective from 2016, the Act established a clear standard to provide speedy and fair compensation aid for victim of environmental pollution by easing the burden for demonstration. | Hyundai Steel has purchased an environmental liability insurance to ensure victims receive rapid compensation, and strengthen environmental supervision for all business sites to prevent environmental related incidents. |

| Special Act on the Improvement of Air Quality in Air Control Zones | Taking effect from 2020, the Act seeks to improve air quality by controlling sources of air pollutants in a broad and systematic way accordingly to regional characteristics. | Hyundai steel abides to the emission cap regulation and comply with the mandatory installation of telemonitoring systems(TMS) on smokestacks to ensure that all of our business sites comply with the smokestack emission cap regulation. |

| Act on Registration and Evaluation of Chemical Substances | Taking effect from 2015, the Act regulates chemical substances manufactured in or imported to Korea, and mandates the 'registration of chemical substances', including their characteristics and risks, before manufacturing or importing chemical substances. | In 2018, Hyundai Steel registered seven existing chemical substances subject to registration. In 2019, when range for the subject of registration expanded, 18 substances were additionally registered, and is undergoing thorough management to register the annual quantity within the deadline. |

| Chemical Substances Control Act | Taking effect from 2015, the Toxic Chemicals Control Act (started from 1991) has been amended, reinforcing the harmful chemical substance management standards and punishment regulations. | Hyundai Steel made thorough preparation with facilities investments and received consulting by specialized agencies before the management standards for hazardous chemical handling facilities came into effect in earnest, and was rated 'appropriate' in the regular inspections conducted for the first time after its effectuation. Our chemical incident prevention and management plan implemented in 2021 was also rated as appropriate. As the number of chemical substances designated as toxic substances increases, we are taking a preemptive response by thorough monitoring. |

| Act on the Allocation and Trading of Greenhouse-gas Emission Permits | Taking effect from 2012, the act includes the information on the fundamental plans for the emission trading system, allocation of emission rights as well as transactions, which targets to effectively reach the national greenhouse gas reaction goal by introducing the trading system. | Hyundai Steel is subject to the carbon credit trading system and carries out GHG reduction activities to comply with the Act. Every year, we measure and transparently disclose GHG emission data verified by an external assurance agency. |

| Framework Act for Carbon-neutral Green Growth in Response to Climate Crisis | Taking effect from 2022, this act sets forth the government's vision to achieve carbon neutrality by 2050 and GHG reduction targets for 2030. It also lays the groundwork for engaging in international GHG reduction activities in accordance with Article 6 of the Paris Agreement by establishing policies to adapt to climate change, foster green industries, raise climate response funds, and set the key factors required for fostering carbon neutral policies. | With the goal of achieving carbon neutrality by 2050, Hyundai Steel has set mid- to long-term strategies and directions aligned with NDC. In addition, we have established a carbon emission reduction system, setting voluntary reduction targets, and are implementing detailed action plans. |

Operation of the Environmental Improvement Council

Hyundai Steel operates the Environmental Improvement Council in order to transparently share information and exchange views about environmental issues and the environmental improvement of our steelworks. The Council is composed of 18 members representing Dangjin City, Dangjin Municipal Council, Chungcheongnam-do Province, civic groups and local residents, and its operation is supervised by Dangjin City to ensure transparency. Being constantly operated since 2019, the council has been sharing issues including current environment management, actions for reducing greenhouse gas, improvements of blast furnace bleeders 1) and is searching for solutions regarding regional development.

Main activities

- September 2019 Convened the first meeting of the Council.

- December 2019 Established the operating regulations of the Council.

- January 2020 Discussed the disclosure of the environmental data of the Dangjin Integrated Steelworks, disclosed real-time air pollutant emission concentrations through the website of Dangjin City.

- February 2020 Started to operate a sprinkler truck and a sweeper truck to reduce fine dusts near the Dangjin Integrated Steelworks.

- March 2021 Disclosed, through the website of Dangjin City, odor data compiled from the automatic odor measuring systems installed at three locations in the southern part of the Dangjin Integrated Steelworks.

- October 2021 Agreed to assess fine dust around the Dangjin Integrated Steelworks in joint with Dangjin City and a private environmental monitoring agency(Feb. 2022~Jan. 2023)

- February 2022 Installed an electronic board near the Dangjin Integrated Steelworks and disclosed environmental data of the Dangjin Integrated Steelworks in real time, including air quality data

Regular Environmental Improvement Council meetings between Dangjin City and Hyundai Steel.

Regular Environmental Improvement Council meetings between Dangjin City and Hyundai Steel.- 1) Blast furnace bleeder: A safety valve that is installed on the top of the blast furnace that produces molten steel. In case when the internal pressure and temperature of the furnace exceeds over a certain point, it opens the bleeder to control both pressure and temperature. During a safety check or a maintenance process, it releases the remnant gas.

Investment in Environmental Improvement and GHG Reduction

Hyundai Steel decided to make additional investments of KRW 490 billion for five years from 2021 to 2025 in order to improve the environment and reduce greenhouse gas emission. This investment decision brings the total amount of our investment in the environment to KRW 1 trillion over 10 years, including KRW 510 billion invested from 2016 to 2020. With that, the Company is able to build a more advanced environmental system and make preemptive responses to environmental issues.

Hyundai Steel plans to install a coke dry quenching system(CDQ) by 2025, where waste heat is recovered from the coke cooling process and recycled into steam and electricity. With this investment, we expect to reduce GHG emissions by more than 500,000 tons a year. The Company is planning to improve the energy efficiency of its steel mills by using heat exchangers and recovering waste heat. We will also improve the environment in all possible ways, such as improvement of facilities preventing pollutants and dusts, slag recycling and expansion of in-house waste treatment.

Systematic Operation of Environment Meeting

Hyundai Steel systematically organizes environment meetings to raise the management's awareness and build a consensus across the Company about the importance of environmental management. Company-wide meetings take place every quarter, while environment meetings at the steelworks and those among environmental managers are held every month. In particular, company-wide meetings serve as an effective channel of communication between the management and our employees about environmental issues. The purpose of these meetings is to share examples of environmental improvement and pending issues at each business site, analyze risks and discuss solutions. In 2021, the company-wide meeting took place twice(10 agenda items), the steelworks environmental meeting was held nine times(40 agenda items), and the environment managers' meeting was held 10 times(55 agenda items). These meetings brought about tangible results, including the installation of a denitrification facility in the heating furnace, where KRW 75.9 billion was invested, to reduce environmental pollutants.

- Share environmental

improvement

cases and issues -

Company-wide

Environment Meeting -

Environment Meeting

of Steelworks -

Environment Managers'

Meeting