Circular Economy

Hyundai Steel is taking the lead to create a circular economy for future generations by emulating the value of steel, in the sense that it resembles the circulation of nature. For this, we establish a solid foundation for eco-friendly management by putting in place production systems to achieve carbon neutrality, as well as striving to protect the environment by reducing pollutants.

Installation of Nitrogen Oxide Reduction Facilities

The cold rolling process and the rolling process involve high-temperature heat treatment in order to secure the workability of rolling and right properties required for finished steel products. As a result, the reheating furnace in hot rolling mill and the annealing furnace in cold rolling mill emit a large amount of nitrogen oxide(NOx) out of combustion. NOx is a major precursor to ultrafine dust, and hence the government is implementing strict policies to control air pollutant emissions at business sites.

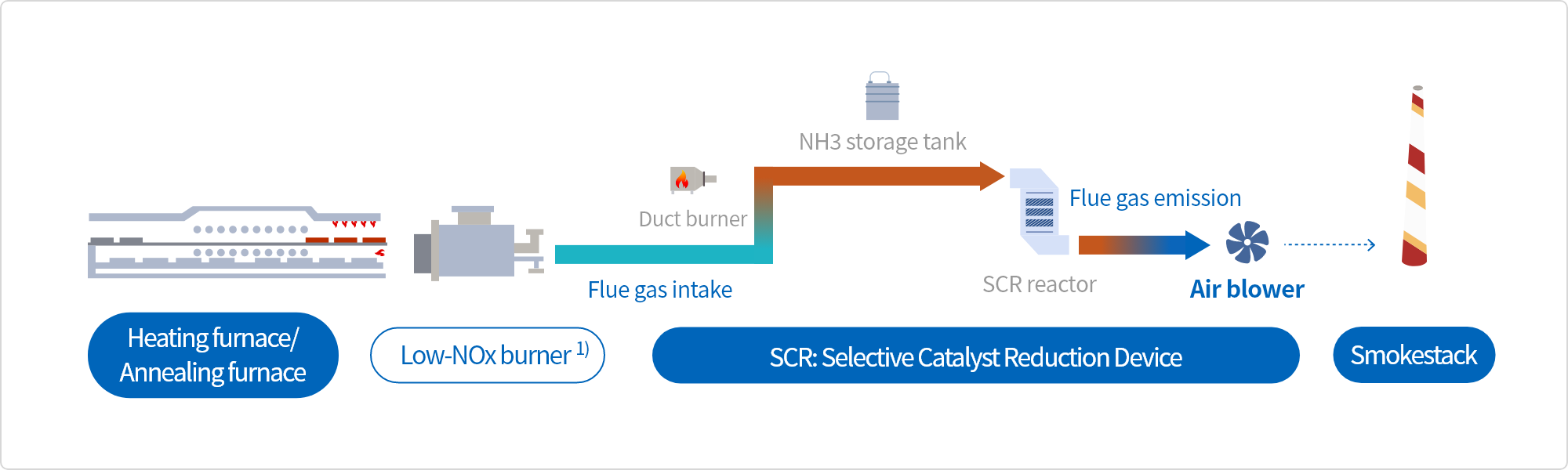

Under these circumstances, Hyundai Steel has adopted multi-stage combustion and low-NOx burners at a number of facilities to reduce NOx emissions. We have also introduced Selective Catalyst Reaction(SCR), a low-NOx combustion technology, to the annealing furnaces of the continuous galvanizing lines(CGL) at our domestic business sites. SCR, the most effective NOx reduction technology in terms of NOx reduction efficiency and stability, was preemptively applied to the 3CGL annealing furnace at the Suncheon Works in 2018, the 2CGL annealing furnace at the Dangjin Integrated Steelworks in 2019, the 2CGL annealing furnace at the Suncheon Works and the 1CGL annealing furnace at the Dangjin Integrated Steelworks in 2020.

In 2021, the installation of a total of 21 NOx reduction facilities started at the heating furnaces for hot rolling and rebars in the Dangjin Integrated Steelworks and the rolling heat treatment facilities in our steelworks in Pohang, Incheon, and Suncheon. Among them, 7 are slated to start up operation in 2022 and the other 14 in 2023, with which NOx emission is expected to decrease to about 40ppm.

- 1) Low-NOx burner: A high-performance burner which shortens combustion gas residence time by adjusting flame temperature and oxygen concentration during combustion, in order to increase combustion efficiency and reduce NOx emissions. It helps to reduce air pollutant emission and save fuels.

Hy Cube Project for low-carbon products manufacturing

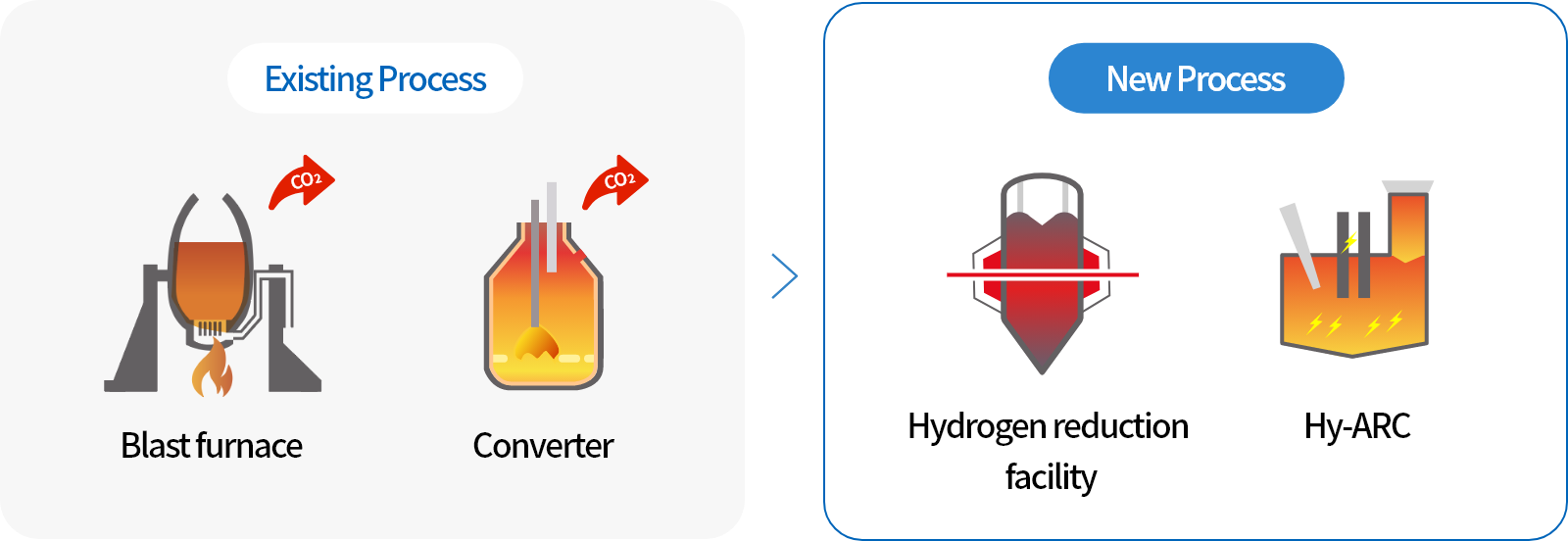

Hyundai Steel is planning to implement a carbon-neutral manufacturing system called 'Hy-Cube'1), and introduce a 'hydrogen-based steel manufacturing system' in line with the 2050 carbon neutrality scenario and the 2030 NDC(Nationally Determined Contribution).

In the steel industry, steel products are manufactured by either of two processes; 'blast furnace' and 'electric arc furnace'. A blast furnace melts raw materials such as coal, while an electric arc furnace uses electrode column to melt steel scrap into molten iron. Carbon emission of steel products manufactured in an electric arc furnace is only 25% of that of steel products made in a blast furnace, due to the characteristics of their raw materials and manufacturing process itself. Hyundai Steel has the largest production capacity of electric arc furnaces, producing over 10 million tons of steel annually.

Hy-Cube is the unique integration manufacturing system that is based on the hydrogen gas manufacturing process. As an advanced process built upon the existing electric arc furnace, a 'brand new Hy-Arc' melts raw materials, remove impurities and add substances all in one process. Created based on the strength of Hyundai Steel, Hy-Cube enables us to make flexible responses in terms of raw materials, manufacturing processes, and products when it comes to attainment of carbon neutrality.

△Raw materials: Integrating Hydrogen Reduced Iron and Molten Iron, as well as utilizing the original furnace by appropriately applying AI.

△Manufacturing process: Creating an organic connection by optimizing unique characteristics of each raw materials such as Hydrogen Reduced Iron and Molten Iron in the manufacturing process.

△Products: Applicable to the whole range of products including quality steel sheets produced from the blast furnace, and bars and sections produced from the original electric arc furnace.

Hyundai steel aims to do more than simply cutting carbon emission from manufacturing process. Our ultimate goal is to produce high-performance products through a Hy-Arc using steel scrap, carbon-neutral molten iron(molten iron produced in a blast furnace), and direct-reduced iron(DRI)2), and thus supply carbon-neutral products, that would otherwise not have been possible under the conventional electric arc furnaces, to the market. Hyundai Steel has been participating as a leading research institute in one of research tasks for carbon neutrality under the Ministry of Trade and Industry since 2015 and has developed carbon reducing technologies for electric arc furnaces. Simultaneously, to actively implement technologies for low-carbon steelwork operations, Hyundai steel will work with the Korea Institute of Energy Research from 2022 May. A business agreement has been made to cooperate in carbon capture and storage, hydrogen production and improvement of energy efficiency. We are also working together with Korea Institute of Geoscience and Mineral Resources for cooperation for the optimum usage of steelwork materials.

- 1) Hy-Cube: Hy³, Hyundai Hydrogen Hybrid

- 2) DRI: Solid Iron created when the Iron ore is heated below the melting point and is added with carbon monoxide and hydrogen.